Realising the potential of new print head technology

42 Technology helped develop an innovative ink delivery system for Xaar. It enables them to bring the next generation of high speed, commercial digital printing technology to market faster, and at lower cost

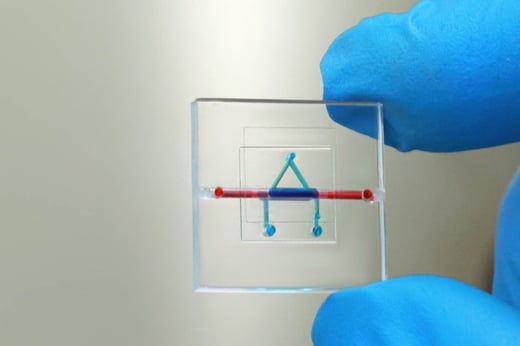

The Hydra recirculating ink supply system was designed to make it much easier to develop prototype printing systems, based on Xaar’s award-winning 1001 printhead, by removing one of the most time consuming, costly stages in the development process.

Innovation

In the past, manufacturers have had to spend time matching their proprietary inks, delivery system and the intended printable surface with the head. Whereas they can now buy an ‘off the shelf’ unit that supports a wide range of fluid types, viscosities and operating temperatures as well as different printhead orientations.

42 Technology and Xaar developed the initial concept and architecture for a new pumped ink delivery system. It was then further optimised by Xaar’s in-house team of product engineers.

What we achieved for our client

The resulting launch of the compact small footprint unit strengthen the company’s position in the fast-growing commercial inkjet printing market. Xaar shipped almost 50 Hydra units in the first three months of sales and experienced a huge increase in demand for its 1001 printheads.

“42 Technology has not only helped develop a market-winning system to boost sales of Xaar’s 1001 heads. They also optimised our product development strategies. Their engineering team took a fresh look at our new product development process and, utilising their own in-depth experience across a variety of markets, worked with our in-house team to introduce some significant improvements. Hydra, which is already a sales success, is the first of a number of breakthrough products that we expect to deliver from this improved approach.”

Teamwork

42 Technology’s project managers and engineers worked as an integral part of Xaar’s in-house resource. A detailed product specification was agreed. Concepts were developed and investigated using advanced hydraulic modelling techniques before sub-systems were designed and tested. Only once a thorough understanding had been established was a detailed system designed and developed.

Hydra delivers ink on demand to four Xaar 1001 printheads. It is easy to operate with just three buttons and can very accurately maintain the ink’s operating parameters. Parameters such as pressure, temperature, viscosity and flow – across the head.

Accurate control is essential in delivering high-quality print and an easy to use system. Hydra is also scalable, allowing manufacturers to rapidly develop large format, 1001-enabled printing technologies by using multiple units simultaneously.

The units are designed to handle a full range of fluid types including high viscosity and heavily pigmented inks.

If you would like to find out more please contact Peter Brown:

answers@42T.com | +44 (0)1480 302741

Related Articles

Manufacturing & Automation, Industrial

Root-cause identification of manufacturing variability

Healthcare & Life Sciences, Innovation

Strengthening DLOC’s organ-on-chip patents

What will you ask us today?

We believe in asking the right questions to drive innovation; when we know the right questions, we generate the ideas to answer them.