Sustainability & Net Zero: boosting competitiveness through strategic innovation

October 2022

by 42T's Net Zero & Sustainability team: Dr Peter Brown, Katie Doig, Tim Hartley, Rob Mueller & Francesca Stephens

How harnessing innovative product design and manufacturing has a whole range of business benefits

Sustainability and net zero are two critical themes that will drive significant innovation in the 21st century for most industries. The facts are stark.

- We must reduce our emissions by 50% by 2030 and achieve net zero by 2050 or dangerous climate change will become a reality, quite possibly within our lifetime or that of our children.

- We are already using up the Earth’s resources 73% quicker than it can provide for us. Infinite growth is an impossibility that many economic models and politicians fail to acknowledge.

With a growing global population and a desire for billions of people to achieve the lifestyle of the affluent West, this challenge won’t get any easier the longer we wait to make the required changes.

Sustainability and net zero is good for all businesses

Even for those who don’t accept that these are strong drivers, the benefits of greater sustainability within an industry or an individual company can be significant.

- Delivers on customer or public expectations

- Builds business resilience including supply chain security

- Gains an early competitive advantage, particularly if challenging regulatory changes are in the pipeline

Every economic sector needs to play a role in addressing these challenges and action must now be taken urgently. However, it can be difficult to decide on the best actions to take whilst remaining competitive and profitable.

This is often exacerbated by uncertainties regarding the technology roadmap required to deliver the necessary changes, or a fluctuating political situation that leaves the regulatory landscape patchy, unclear, and liable to change with every electoral cycle.

On top of this, whilst customers and (some) regulators may demand change, they are often unwilling to pay more or change their lifestyle to achieve these changes. Will most of the West go vegetarian? Will we really give up our love of international travel? This seems highly unlikely.

Innovation and clever design

These drivers and constraints make for a complex problem and innovation will be key to finding the right solution space. The design of our products and the associated manufacturing processes will need to be reimagined – sometimes from the ground up – to achieve this.

- Products and packaging will need to be increasingly designed for the circular economy: recyclable, reusable, repairable and made with renewable materials.

- Manufacturing processes will need to be more efficient, consuming less energy and water whilst producing less waste

- Energy generation and distribution will need to eliminate fossil fuels where possible, using all types of renewable generation available and making the truly Smart Grid a reality, to allow for distributed generation and storage of electricity

- Off-grid applications such as many modes of transport may need to make one of the hardest transitions: towards using alternative fuels such as hydrogen

The future belongs to those who adapt faster

Those companies who move quickest to establish economically viable products and processes that are both sustainable and address net zero targets will undoubtedly gain a competitive advantage.

Not only will they reap the rewards of complying with regulations first and the gratitude of their customers, but it is also likely that they develop ideas, technologies, products and processes that can be used broadly, yielding the possibility to generate further commercial revenue.

So what? Nothing written here is surprising or unknown for the enlightened reader, but it is a lot easier to identify the problem than the solution.

Multidisciplinary perspective and expertise

That is where 42 Technology (42T) comes in. We are a science, engineering and technology firm with a team of 50 (and growing!) scientists, designers and engineers that exists to tackle our clients’ challenges where innovation and technology are necessary to achieve hard objectives, especially where the solution requires multidisciplinary teams working in a highly collaborative manner.

We have a track record of delivering projects that yield innovation in product design and manufacturing process development that positively impacts the drive towards sustainability and net zero.

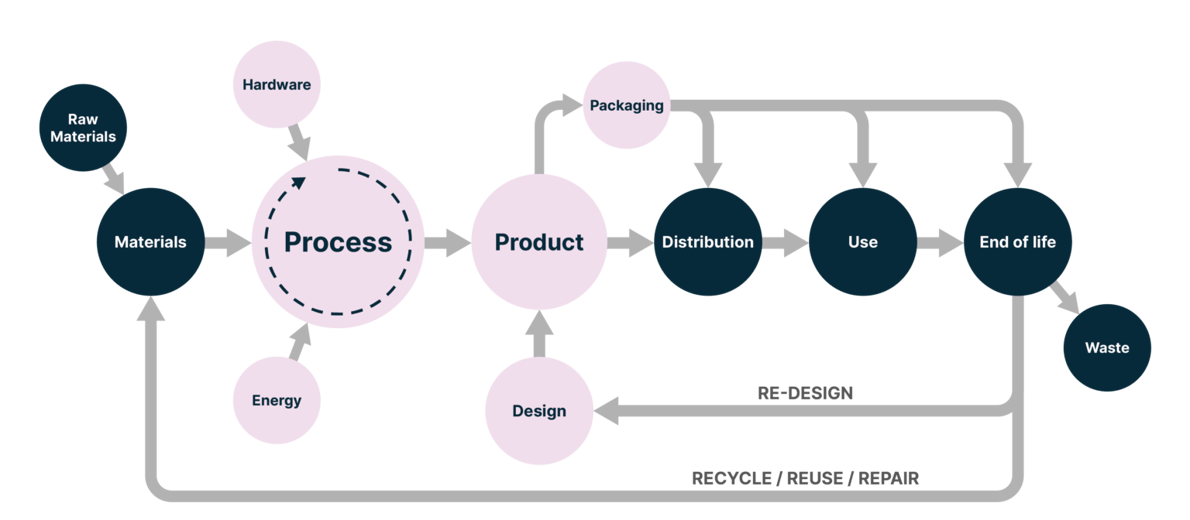

Considering products and manufacturing processes in isolation for now (whilst acknowledging that everything is interlinked in our complex world) a generalised, simple flow-diagram of the design and production of a typical product might look like the following:

The items in pink are where we contribute strongly:

- Machine development

- Manufacturing process development

- Energy generation, storage, and distribution

- Product design

- Packaging

- We even get involved in the distribution sector due to our work in secondary packaging and transport which is particularly sensitive due to the rise in popularity of e-commerce

Examples of our work

Cooling tunnel optimisation: a cooling tunnel formed a critical process step in the manufacture of a food product. By examining the operating conditions of the tunnel, including a detailed analysis of the heat and air flows, we recommended modifications that led to an 11-fold increase in performance whilst maintaining product quality.

Reduced water usage in a manufacturing process: our client is a food manufacturer that needed to reduce water consumption during the manufacturing process of a particular product. We analysed the whole process from beginning with the view to identifying step-changes improvements. We succeeded saving up to 50% in water usage.

Removing single-use plastics from packaging: our client is a global supplier of products that contain single-use plastics and, for one product in particular, wanted help to identify a sustainable alternative. We analysed the requirements of the material from the point of view of multiple stakeholders, including the end-user and manufacturer, and screened dozens of potential alternatives from paper-based materials to bioplastics. Eventually, three were shortlisted and after further analysis, one was taken forwards by the client.

Often, clients present us with a challenge that they have already decided upon and ask us to deliver a solution. We’re good at this, so it’s perfectly sensible approach for both parties. However, this only taps into part of the expertise we bring.

In addition to bringing a winning combination of innovation and pragmatism to our clients’ challenges, we are also completely independent and operate across multiple industries.

Why an external perspective is incredibly valuable

- We can come to problems with a fresh perspective

- Independent evaluation - we don’t have an axe to grind or a new widget to sell which may skew someone’s analysis

- We can bring technologies, solutions or thinking from unrelated industries to bear on novel areas

As a result, it can be beneficial to have 42T undertake a complete review of a product and/or it’s associated manufacturing process. Ideally, we would have a blue-sky remit to identify innovative projects with the potential to deliver real change, subject to the constraints of that particular industry or company.

Of course, many companies regularly perform such reviews internally. But as they are internal reviews, they are potentially subject to the constraints of ‘industry norms’ and groupthink.

Process overview

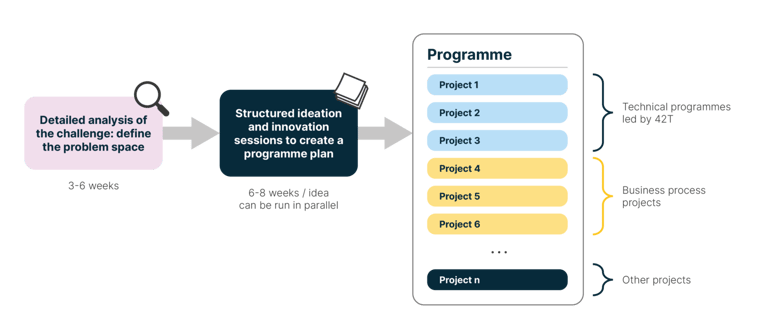

For example, a review of a manufacturing process might take the following form:

-

- Agree the key objectives of the client. What are the parameters to optimise and what are the constraints?

- Background reading and documentation provided by the client.

- Site visit for 1-2 days. Detailed tour of the line and conversations with a representative number of people who have worked on the line

- - Operators who work at the ‘coal face’

- - Executives

- - Managers

- - R&D team

- Talk to other important stakeholders, such as key customers and suppliers

- Perform a detailed analysis. We are scientists, engineers and designers and we would restrict our analysis to this broad scope.

- Present our results and recommendations.

These recommendations are likely to be a portfolio of projects, some of which will be technical, a subset of which 42T may be best placed to take forwards. Others may be best handled by the client or other 3rd parties, depending on the scope.

Where 42T is the best team to take the projects forwards, we will be able to proceed at pace as we are already up the learning curve. Also, as the progenitor of the project, the overall risk that the project might fail to deliver or run late will be reduced further.

A summary of the overall process is shown schematically below:

At the end of the initial steps of this process, our clients will have the advantage of knowing that an independent, highly skilled, and experienced team will have formed a set of recommendations that will make a difference.

Case study: energy efficiency in a vending machine

Our client knew that it wanted to reduce the energy consumption in a vending machine for both hot and cold drinks, but its preferred method was not cost-effective.

We were given free rein to identify ways in which greater energy efficiency could be achieved, so undertook a full analysis of the energy flows of the system to characterise the challenge and to inform the subsequent ideation process.

We conceived of three plausible ideas and investigated them for energy savings, retrofit-ability, patterns of use and cost effectiveness. These ideas led to a 45% reduction in energy consumption.

Case study: minimising plastic in landfill

Our client distributes and sells its product in plastic packaging. Almost all of it - nearly a million per annum - ends up in landfill. Within the context of eliminating single-use plastics, this is clearly unsustainable. Our client asked us to come up with a solution. However, the packaging protects the contents well and is easy to handle - both by the end-user and in distribution - so there were significant constraints for any alternative solution.

We started by visiting and interviewing the key stakeholders including upstream and downstream partners. This put human faces to the problem and enabled us to construct a typical product journey. We then assessed the requirements, constraints and, importantly, the risks of any ideas we generated to solve the problem.

Based on this work, we identified opportunity areas where there could be improvements. Some were technical where 42T could take the development forwards. Other suggested improvements included supply chain optimisation. The concepts taken forward by 42T included materials substitution, materials elimination and change of form-factor of the packaging.

A plan for meeting the future

In summary, the world of product development and product manufacturing is facing serious challenges, the likes of which we have never seen since the dawn of the Industrial Revolution. These challenges are complex and do not have easy solutions.

42T is perfectly placed to help companies facing the sharp end of these challenges. We help to identify the right ideas and to execute them quickly and successfully.

We are currently helping companies address sustainability and net zero challenges in product design and manufacturing. Read some of our case studies to find out how.

If you would like to find out more, please contact Peter Brown:

answers@42T.com | +44 (0)1480 302741

Share this article:

Related Articles

Consumer, Sustainability

The refillable revolution - the sustainable future of grocery shopping

Sustainability, Industrial

The surge in the global Blue Economy - what role for deep tech?

Sustainability, Industrial

The hydrogen economy - solving difficult challenges towards energy transition

What will you ask us today?

We believe in asking the right questions to drive innovation; when we know the right questions, we generate the ideas to answer them.