The value of sustainable materials data & impact on design thinking

May 2022

By Chris Taylor, Senior Consultant at 42T

With increased awareness of the unfolding environmental crises, manufacturers and designers are realising there is a need to change how we design and make goods.

More and more brands are deciding to make a conscious effort to embrace sustainable design and manufacturing practices. When developing sustainable products, projects will sometimes investigate reducing the environmental impact through material changes as well as taking a less linear approach to manufacture, use and disposal.

We have worked with several clients on this very topic, which has prompted an internal discussion relating to the availability of sustainable material property data – or more specifically, the lack of it.

The problem of data & understanding

To design and develop anything, we need to understand the problem being solved and the conditions of operation. This eventually leads us to decisions on form and function, and consequentially of material and manufacturing choices.

Fortunately, the consumer mindset is changing and products that have well thought out life cycles, reduce materials, and consider the ecological impacts, are more likely to be positively received by consumers. However, one of the inherent problems with the change to sustainable materials is that they are typically developed to solve a particular problem. Little to no further research subsequently takes place into what other potential applications they might be suitable for.

While the design community is striving to utilise techniques like Design for Disassembly, Design for Longevity, Design for Reliability, Design for Dematerialization, and Design for Modularity, among others, there remains this void in sustainable material property and processing data for the newer more exotic material developments.

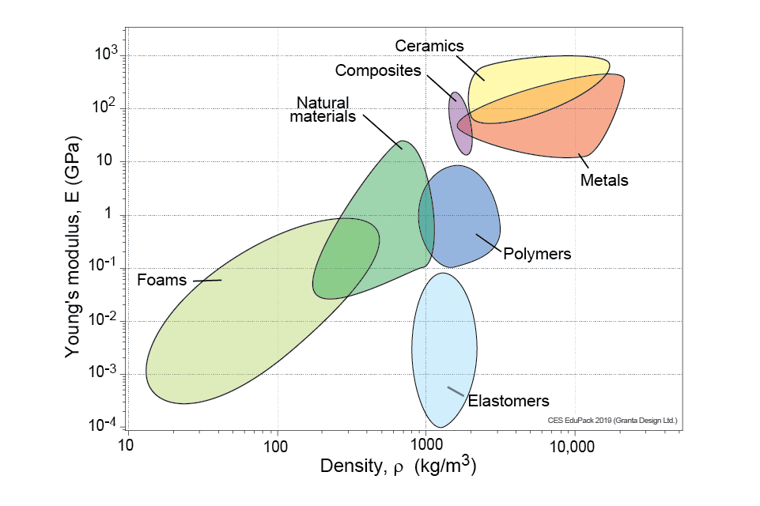

Young Modulus vs Density - materials property data chart created using CES EduPack 2019, ANSYS Granta © 2020 Granta Design

It is vital for designers to understand what potential alternatives exist for their often-constrained palettes, due to the 'tried and tested' nature of some industries. Especially those that produce high-value low-volume products, that provide a very specific function, for which a significant change would require extremely costly rounds of re-qualification and certification.

The situation

Climate change is rapidly becoming an issue that everyone has a part to play in solving. As designers of products and processes, we are responsible for leading the way in making the necessary changes in how products are designed and built in order to contribute to tackling the threat. Product design and manufacturing are great for economic growth and social development.

However, product design and manufacturing is also responsible for 20% of global CO2 emissions and consumes 54% of the world’s energy, according to the World Economic Forum (WEF). As a consultancy involved in the design and development of new products, we have a responsibility to educate ourselves and our clients on the possible alternatives and options to reduce the carbon footprint of products.

We have worked with clients on several sustainability-led projects, for example reducing the waste water or energy usage of processing during product manufacture. While the review of processes is an important and beneficial step, this is only part of the overall problem.

It is widely acknowledged that a large portion of the carbon debt manufacturers build up in their products is a result of decisions at the R&D stage. This is primarily regarding the materials used to make the product and the processes to manufacture and build it. But without suitable material property data it is extremely difficult for designers to technically justify a switch to alternative, more sustainable, materials.

The challenge

While there are certainly some interesting and exciting developments being made in the world of materials science, with some new and innovative natural materials emerging for varying applications, the thought process often ends with the specific application for which the material has been conceived.

This can mean that further characterisation testing is not carried out and more comprehensive material property data is not generated. More importantly, such material property and performance data may not be shared with the wider engineering public!

The opportunity

It is widely recognised that data is valuable. For designers to make informed decisions relating to their future designs, more needs to be done to capture and share appropriate material data relating to sustainable materials.

A good example of how an industry has come together to create such a forum for sharing information and tools is the Sustainable Apparel Coalition (SAC) - a global, multi-stakeholder, non-profit alliance for the fashion industry, including brands such as Rapha, Salomon and allbirds. Also, manufacturers such as Belda Llorens, Du Pont and Gore, as well as some major academic and government bodies.

With the wider realisation of shared responsibility, there is now greater scope for similar consortiums and coalitions such as the SAC in the wider product development community, possibly including a new more open community of shared research into the new and exciting materials being developed.

One such group is the Material Designers (MaDe) project which, like the SAC, aims to connect creative professionals and students, industrial partners, and institutions to accelerate the circular economy. This then allows engineers and designers to do more at the R&D stage to ensure that new products and processes are as environmentally responsible as possible.

Sustainability partner

At 42T, we are actively working to develop our sustainable materials and life cycle knowledge and set out to create our own internal resources. We aim to educate ourselves and our clients about possible alternative materials identified on opensource platforms such as Materiom, Material Designers, Material Driven, and many others.

We can support designers and manufacturers, to improve the sustainability of their products and processes. Our track record is in helping clients create more environmentally responsible products and processes, and experience in designing with sustainability in mind through innovative approaches to materials science and testing.

If you would like to find out more, please contact Chris:

answers@42T.com | +44 (0)1480 302700 | www.linkedin.com/in/taylorsengineeringdesign

Chris is team-centred, thorough, and articulate. He has designed and delivered products for a variety of industries over the last 16 years. His experience is spread across a variety of sectors, including energy, consumer products, IoT and Medical.

Share this article:

Related Articles

Consumer, Sustainability

The refillable revolution - the sustainable future of grocery shopping

Sustainability, Industrial

The surge in the global Blue Economy - what role for deep tech?

Sustainability, Industrial

The hydrogen economy - solving difficult challenges towards energy transition

What will you ask us today?

We believe in asking the right questions to drive innovation; when we know the right questions, we generate the ideas to answer them.