Design choices for plastics to reduce their environmental impact

May 2021

By Tim Hartley - Consultant at 42 Technology

With the issue of climate change and our impact on our planet in the forefront of the general public's consciousness, the pressure for industry to demonstrate green credentials and contribute to the collective effort to reduce emissions is ever increasing.

Consumers are no longer content with products that demonstrate apathy towards reducing humanity’s impact on the planet. Over 80% state that they prefer to buy from sustainable sellers [1]. Eco-credentials give a product a market edge and one of the best and most easily discernible ways to achieve this is the material choices that make up the product or its packaging.

Foremost among these material choices is the use of plastics. Whilst often the first instinct for many is to try and remove plastics completely, this may be detrimental to both the product and environment in the long term.

There is significant interest in bioplastics for the disposable food and drinks packaging industries.

There is significant interest in bioplastics for the disposable food and drinks packaging industries.

Plastics have been villainised for many years due to their lack of biodegradability and tendency to cause very visible damage to natural landscapes and their inhabitants. These issues, however, are usually caused by the way that the materials are handled and used, rather than a problem that is caused by the material itself.

Plastics have become essential for many different industrial and domestic properties. And completely removing plastics from manufacturing would leave a gaping hole which would be very difficult to substitute with other materials.

For example, the elimination of plastics would cause much greater food wastage, an increase of high energy materials produced, and greater numbers of trees cut down. This would all contribute very heavily towards climate change.

While plastics appear to be persisting for the foreseeable future, there are many different things designers and engineers can do to reduce the impact of their designs on the planet.

Firstly, the simplest thing that designers can do is to reduce the amount of material in their product and packaging. All material comes with its own associated carbon cost, and simply using less of it is possibly the most cost-effective way of doing this.

Secondly, creating products that are re-usable, or adapting a business model that allows for products to be re-used can drastically reduce the associated carbon in a similar way to using less in a new product.

This model can also have financial benefits. If the packaging for the product is reused it reduces material and processing costs of having to make the packaging from a raw material.

Winners of the Earthshot prize 2023, Notpla, make packaging from brown seaweed & plants and are pictured here presenting at GRIPS 2023 conference.

Where possible using plastics that can be recycled after use is another crucial change that can be made, as the carbon generated by creating a product where the plastic is recycled generates far less emissions than virgin plastics.

This can potentially lead to more difficulties with product design as mixed material products are far more difficult to recycle. And some plastics are not yet currently recycled, limiting the range that can be designed.

Lastly, the plastics could be replaced with bioplastics including bio-degradable plastics. Studies have shown that the emissions from bioplastic generation are around 2.5 times lower [2] for bioplastics. And if they are also bio-degradable they are likely to generate less methane in landfills than common plastics, a gas which is significantly worse than carbon dioxide for climate change.

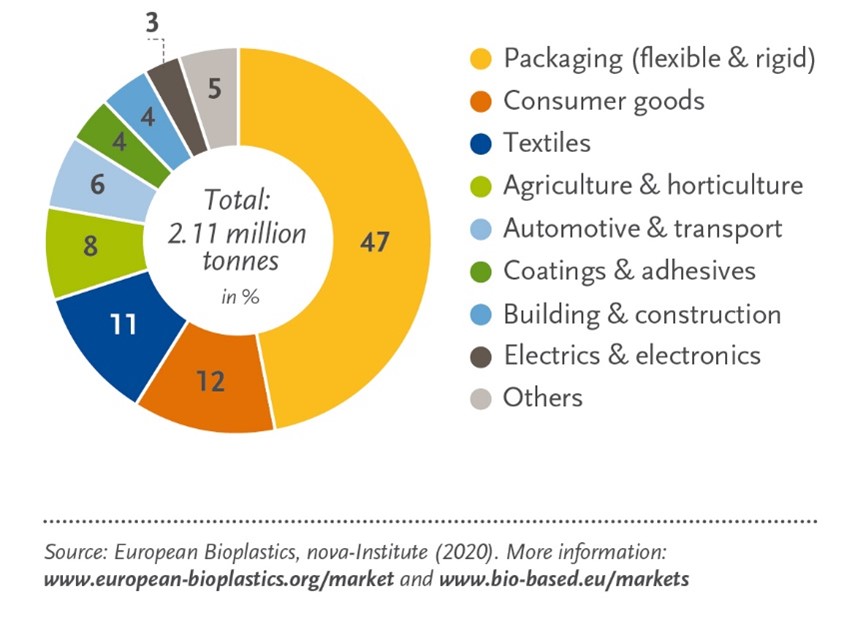

Bioplastics are experiencing a surge in research effort and commercial development. The cost of producing these plastics is consistently falling due to this effort and with a more secure feedstock base are making them a more and more attractive alternative. Of those on the market common replacements for standard plastics include starch-based plastics, cellulose based plastics and aliphatic polyesters.

Bioplastics are well suited to applications where the nature of the products that they are being made into prevents them from being recycled, either due to heavy contamination, mixing materials or where the plastics are intended to be left in the environment for a period of time but last longer than other temporary materials would.

For example, film lids for food trays are essential to preserve the food contained within them for the amount of time required. However, recycling these films presents an issue and most recycling systems are unable to process them. Bioplastics may present a solution that may even offer superior properties to their conventional counterparts.

Researchers have developed an edible film formed of thermoplastic starch derived from cassava. In addition to its biodegradability, it has antimicrobial properties, a feature that is increasingly sought after in a world dealing with the repercussions of the global Covid-19 pandemic. [3]

The techniques outlined above for reducing the environmental impact are a starting point for product design or redesign. The exact method of product improvement will depend on a variety of factors including manufacturing routes, business model and likely consumers.

One or more of the techniques could be employed to different levels, and for each company the desired end result may look very different, but each contributing to the collective target of reducing climate change.

At 42 Technology we have experience with helping our clients with sustainable redesign.

As an example, our client was looking to replace their medical single-use plastic product with a more sustainable alternative. 42 Technology carried out comprehensive research into alternative sustainable materials with particular consideration given to compliance with forthcoming EU regulations.

A detailed MECE diagram was produced to represent all the possible materials. This led to high volume compostable plastics being recommended for short-term needs and 'up and coming' materials for longer term development.

Our recommendations were presented in a final review with various client stakeholders and a development roadmap was prepared to progress next generation products.

2 - https://drawdown.org/the-book

Photo courtesy of: https://unsplash.com/photos/SRFOOdORhKw

If you need help updating existing products or designing new ones to generate fewer emissions, or to work with bioplastics, please contact us at answers@42T.com.

If you would like to find out more please contact Tim:

tim.hartley@42T.com | +44 (0)1480 302700 | www.linkedin.com/in/tim-hartley

Tim is a consultant at 42 Technology with experience in conceptual design, development, testing and prototyping. He has worked on many different products from a range of industries, from surgical devices to food and beverage handling systems, drawing in knowledge from other sectors to achieve the client’s goals.

Share this article:

Related Articles

Consumer, Sustainability

The refillable revolution - the sustainable future of grocery shopping

Sustainability, Industrial

The surge in the global Blue Economy - what role for deep tech?

Sustainability, Industrial

The hydrogen economy - solving difficult challenges towards energy transition

What will you ask us today?

We believe in asking the right questions to drive innovation; when we know the right questions, we generate the ideas to answer them.